20th May 2022

20th May 2022Polyurea VS Polyurethane: The Best Protection For My Water Tank?

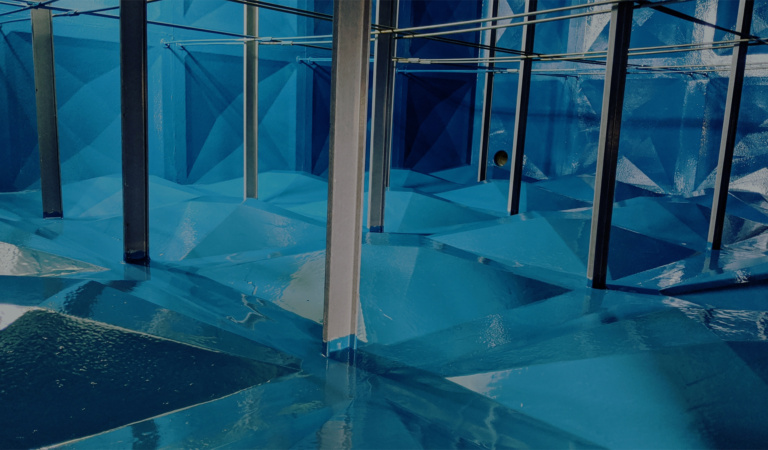

When it comes to water tank relining, our aim at Cold Water Storage is to combat internal surface corrosion, water tank leaks, and bacterial growth.

With our 20 years’ experience in the water industry, we wanted something new – something innovative. That’s what lead us to spray applied polyurea coatings – we are an approved supplier of Line X which excels in Polyurea coating systems.

But what is the difference between Polyurea and Polyurethane? And which has better protection for your water tank?

In this blog, we’ll answer those questions.

Polyurea VS Polyurethane: What’s the Difference?

Metallic components, due to a number of reasons, can become damaged. Whether this is due to corrosion caused by environmental cracks, bacterial growth, or pressure cracks.

Therefore, it is common to now use coating systems on said components to help prevent these damages happening, to extend the life of the product.

The Chemistry of Polyurethane and Polyurea

Both of these coatings are polymers, hence the ‘poly’. Both are two-component system bases, where isocyanate is the common component for both.

For polyurea, the second component is polyether polyamine whereas for polyurethane, the second component is polyether polyol. Compared to polyurethane, polyurea does not require the addition of a catalyst so it can be produced in high moisture conditions.

Performance of Polyurea VS Polyurethane

The polyurea and polyurethane coating systems are incredibly popular and have been successful in the coating industry since they were introduced.

Both polyurea and polyurethane have good chemical and UV resistance and are great for both interior and exterior applications. However, polyurea is best for exterior applications as it is better at UV protection than polyurethane.

Polyurethane and polyurea are both flexible but polyurethane requires re-coatings more often than polyurea does. Although it costs more, then, polyurea has fewer maintenance fees down the line as it requires almost no maintenance at all.

Sometimes the deciding factor comes down to this – the polyurea reaction is much faster than the polyurethane one. It takes less time to not only apply but to cure, also. It also takes fewer coats to achieve a desired level of thickness with polyurea.

Properties of Polyurea and Polyurethane at Cold Water Storage

At Cold Water Storage, both our Polyurea and Polyurethane coating systems are WRAS (Water Regulations Advisory Scheme) approved.

To see the properties of each product clearly, here’s a table:

| Polyurea | Polyurethane | |

| Thickness | 2mm | 1mm |

| Elongation | 300% | 30% |

| Lifespan | 50 – 75 years | 20 – 30 years |

| Application | Hot spray applied | Pour & roll applied |

| Curing Time | 5 – 7 seconds | Minimum 24 hours |

| Guarantee | 20 years | 10 years |

Which is Better: Polyurea or Polyurethane?

With each compound side by side, it’s easier to see which has the advantage.

Not only is polyurea naturally thicker, but it also has a lifespan that is up to 35 years longer than polyurethane. In addition, the curing time is much faster so our team will take less time on clients’ requests. That means there’s less disruption to your business operation as your component will be back up and running in no time.

Polyurea is waterproof and chemical-resistant, making it the ideal product for for water tank protection. That and because it also prevents corrosion, rust, and other deterioration.

However, each project is different – cos, requirements, specifications. Of course, with all the benefits and the maintenance-free nature of polyurea makes it the most cost-effective option. But polyurethane is a good second option for coating applications.

Contact Us: Cold Water Storage

Need any installations, repairs, relines or replacements on your cold water storage tanks? We’ve got you covered.

At Cold Water Storage, we can guarantee expertise thanks to our 30 years of knowledge and experience in the water industry. Get in touch with our team today!

You can call us at 01943 872 311 or email info@coldwaterstorage.co.uk. We’ll respond as soon as possible!